Making containers stackable made loading and transport on large ships feasible and efficientAn intermodal container is a large standardized, designed and built for, meaning these containers can be used across different – from to to – without unloading and reloading their cargo. Intermodal containers are primarily used to store and transport materials and products efficiently and securely in the global intermodal freight transport system, but smaller numbers are in regional use as well. These containers are known under a number of names, such as simply container, cargo or freight container, ISO container, shipping, sea or ocean container, sea van or box, sea can or c can.Intermodal containers exist in many types and a number of standardized sizes, but ninety percent of the global container fleet are so-called 'dry freight' or 'general purpose' containers, closed boxes, mostly of either twenty or forty feet (6.1 or 12.2 m) standard length. The common heights are 8 feet 6 inches (2.6 m) and 9 feet 6 inches (2.9 m) – the latter are known as High Cube or Hi-Cube containers.Just like and, these containers are a means to bundle cargo and goods into larger, that can be easily handled, moved, and stacked, and that will pack tightly in a ship or yard. Intermodal containers share a number of key construction features to withstand the stresses of intermodal shipping, to facilitate their handling and to allow stacking, as well as being identifiable through their individual, unique reporting mark.In 2012, there were about 20.5 million intermodal containers in the world of varying types to suit different cargoes. Containers have largely supplanted the traditional – in 2010 containers accounted for 60% of the world's seaborne trade. The predominant alternative methods of transport carry – whether gaseous, liquid or solid – e.g.

For, the lighter weight -defined is used. Every international shipping container must have a 'CSC-Plate'Two years after McLean's first container ship, the started container shipping on the U.S. East Coast, followed suit between California and Hawaii. Just like 's containers, Matson's were 8 ft (2.44 m) wide and 8 ft 6 in (2.59 m) high, but due to California's different traffic code, Matson chose to make theirs 24 ft (7.32 m) long. In 1968, McLean began container service to South Vietnam for the US military with great success.ISO standards for containers were published between 1968 and 1970 by the International Maritime Organization. These standards allow for more consistent loading, transporting, and unloading of goods in ports throughout the world, thus saving time and resources.The International Convention for Safe Containers is a 1972 regulation by the on the safe handling and transport of containers.

It decrees that every container travelling internationally be fitted with a CSC Safety-approval Plate. This holds essential information about the container, including age, registration number, dimensions and weights, as well as its strength and maximum stacking capability.Longshoremen and related unions around the world struggled with this revolution in shipping goods.

For example, by 1971 a clause in the (ILA) contract stipulated that the work of 'stuffing' (filling) or 'stripping' (emptying) a container within 50 miles of a port must be done by ILA workers, or if not done by ILA, that the shipper needed to pay royalties and penalties to the ILA. Unions for truckers and consolidators argued that the ILA rules were not valid work preservation clauses, because the work of stuffing and stripping containers away from the pier had not traditionally been done by ILA members.

In 1980 the heard this case and ruled against the ILA. Description. The standard castings on the eight corners of each container. The proper is done through a larger oval hole on the top or bottom.Ninety percent of the global container fleet consists of 'dry freight' or 'general purpose' containers – both of standard and special sizes.And although lengths of containers vary from 8 to 56 feet (2.4 to 17.1 m), according to two 2012 container census reports about 80% of the world's containers are either twenty or forty foot standard length boxes of the dry freight design. These typical containers are rectangular, closed box models, with doors fitted at one end, and made of (commonly known as CorTen) with a floor. Although corrugating the used for the sides and roof contributes significantly to the container's rigidity and stacking strength, just like in or in, the corrugated sides cause aerodynamic drag, and up to 10% fuel economy loss in road or rail transport, compared to smooth-sided vans.Standard containers are 8-foot (2.44 m) wide by 8 ft 6 in (2.59 m) high, although the taller 'High Cube' or 'hi-cube' units measuring 9 feet 6 inches (2.90 m) have become very common in recent years. By the end of 2013, high-cube 40 ft containers represented almost 50% of the world's maritime container fleet, according to Drewry's Container Census report.About 90% of the world's containers are either 20-foot (6.1 m) or 40-foot (12.2 m) long, although the United States and Canada also use longer units of 45 ft (13.7 m), 48 ft (14.6 m) and 53 ft (16.15 m).

ISO containers have castings with openings for fasteners at each of the eight corners, to allow gripping the box from above, below, or the side, and they can be stacked up to ten units high. Regional intermodal containers, such as European and U.S.

Domestic units however, are mainly transported by road and rail, and can frequently only be stacked up to three laden units high. Although the two ends are quite rigid, containers flex somewhat during transport.Container capacity is often expressed in ( TEU, or sometimes teu). A twenty-foot equivalent unit is a measure of containerized cargo capacity equal to one standard 20-foot (6.1 m) long container. This is an approximate measure, wherein the height of the box is not considered.

For example, the 9 ft 6 in (2.9 m) tall high-cube, as well as 4-foot-3-inch half-height (1.3 m) 20-foot (6.1 m) containers are equally counted as one TEU. Similarly, extra long 45 ft (13.72 m) containers are commonly designated as two TEU, no different than standard 40 feet (12.19 m) long units.

Two TEU are equivalent to one forty-foot equivalent unit (FEU).In 2014 the global container fleet grew to a volume of 36.6 million TEU, based on Drewry Shipping Consultants' Container Census. Moreover, in 2014 for the first time in history 40-foot High cube containers accounted for the majority of boxes in service, measured in TEU.Manufacturing prices for regular, dry freight containers are typically in the range of $1750—$2000 U.S. Per CEU (container equivalent unit), and about 90% of the world's containers are made in China. The average age of the global container fleet was a little over 5 years from end 1994 to end 2009, meaning containers remain in shipping use for well over 10 years. Forty foot or longer containers typically have a gooseneck tunnel, an indentation in the floor structure, that meshes with the gooseneck on dedicated container. The gooseneck tunnel is clearly visible in the underside of a toppled-over container (first picture), as well as in a container's interior, where it takes the space otherwise covered by wood flooring. Gooseneck container trailer showing twistlock couplings for forty-foot boxes at its four corners.Twenty foot containers on the other hand, frequently have forklift pockets, accessible from the sides (last picture).

A flat-rack container loaded with a small vessel loaded by a.Other than the standard, general purpose container, many variations exist for use with different cargoes. The most prominent of these are (a.k.a. Reefers) for perishable goods, that make up six percent of the world's shipping boxes. And tanks in a frame, for bulk liquids, account for another 0.75% of the global container fleet.Although these variations are not of the standard type, they mostly are ISO standard containers – in fact the standard classifies a broad spectrum of container types in great detail.

Aside from different size options, the most important container types are:. General-purpose dry vans, for boxes, cartons, cases, sacks, bales, pallets, drums, etc., Special interior layouts are known, such as:.

rolling-floor containers, for difficult-to-handle cargo. garmentainers, for shipping garments on hangers (GOH). Ventilated containers. Essentially dry vans, but either passively or actively ventilated.

For instance for organic products requiring ventilation. Temperature controlled – either, and/or heated containers, for perishable goods., for liquids, gases, or powders. Frequently these are, and in the case of gases one shipping unit may contain multiple gas bottles. Bulk containers (sometimes bulktainers), either closed models with roof-lids, or hard or soft open-top units for top loading, for instance for bulk minerals.

Containerized coal carriers and 'bin-liners' (containers designed for the efficient road and rail transportation of rubbish from cities to recycling and dump sites) are used in Europe. Open-top and open-side containers, for instance for easy loading of heavy machinery or oversize pallets. Crane systems can be used to load and unload crates without having to disassemble the container itself. Open sides are also used for ventilating hardy perishables like apples or potatoes. Platform based containers such as:. flat-rack and bolster containers, for barrels, drums, crates, and any heavy or bulky out-of-gauge cargo, like machinery, semi-finished goods or processed timber.

Two 45-foot 'High-cube' containers on a (RoRo) tractor. The 9 ft 6 in height of the boxes is identified by diagonal yellow and black markings on the top corners of the containerBasic dimensions and permissible gross weights of intermodal containers are largely determined by two ISO standards:.:2013 Series 1 freight containers—Classification, dimensions and ratings. ISO 1496-1:2013 Series 1 freight containers—Specification and testing—Part 1: General cargo containers for general purposesWeights and dimensions of the most common standardized types of containers are given below. Values vary slightly from manufacturer to manufacturer, but must stay within the tolerances dictated by the standards. Forty-five-foot containers can be seen sticking out 2 1⁄ 2 feet (0.76 m), as part of the forty foot container stacks at the back of this ship.At stacking load-bearing locations, 40-foot containers are the standard unit length, and 45 ft, 48 ft, and 53 ft all stack at the 40 ft coupling width.

Other units can be stacked on top of 20 ft units only if there are two in a row (40 ft coupling width) but 20 ft units can not be stacked on top of 40 ft units, or any other larger container.The coupling holes require a double male twist lock to securely mate stacked containers together.Non-standard and uncommon sizes Pallet wide containers Pallet Wide containers have about 4 inches (10.2 cm) more internal floor width than standard containers to accommodate more, common in Europe. These containers typically have an internal width of 2.44 m ( 96 1⁄ 8 in), to be able to load either two or three of the 1.2 m ( 47 1⁄ 4 in) long by 0.8 m ( 31 1⁄ 2 in) wide pallets side by side. Many sea shipping providers in Europe allow these, as overhangs on standard containers are sufficient and they fit in the usual interlock spaces (or with the same floor panel the side ribs of pallet-wide containers are embossed to the outside instead of being molded to the inside).The 45 ft (13.72 m) pallet-wide high-cube container has gained particularly wide acceptance, as these containers can replace the 13.6 m (44 ft 7 3⁄ 8 in) swap bodies that are common for truck transport in Europe. The EU has started a standardization for pallet wide containerization in the European Intermodal Loading Unit (EILU) initiative.Australian containers are also slightly wider to optimise them for the use of.48-foot containers The 48-foot (14.63 m) shipping container is a High Cube container in that it is 9 ft 6 in (2.90 m) tall on the exterior. It is 8 ft 6 in (2.59 m) wide which makes it 6 inches (15 cm) wider than ISO-standard containers.

This size was introduced by container shipping company in 1986, and is used domestically in North America on road and rail, and may be transported on deck by ship. This size being 8 feet (2.44 m) longer and 6 inches (15 cm) wider has 29% more volume capacity than the standard 40-ft High Cube, yet costs of moving it by truck or rail are almost the same.53-foot containers. Swift 53 ft Intermodal containerGeneral purpose 53-foot (16.15 m) containers were introduced in the United States in 1989, and are used both in the U.S.A. And Canada, mainly for domestic road and rail transport. They are considered High-cubes, based on their 9 ft 6 in (2.90 m) ISO-standard height.

Their width of 8 ft 6 in (2.59 m) however makes them 6 inches (15 cm) wider than ISO-standard containers. These large boxes have 60% more capacity than standard-height 40-foot (12.19 m) containers, enabling shippers to consolidate more cargo into fewer containers.Generally, North American 53-foot containers were not constructed strong enough to endure the rigors of ocean transport, but in 2007 container carrier introduced the first 53-foot ocean-capable containers.

All new, reinforced 53-foot boxes were built specifically for international trade and designed to withstand ocean voyages on its South China-to-Los Angeles service. In 2013 however, APL stopped offering vessel space for 53-foot containers on its trans-Pacific ships.

Nevertheless, In 2015 both and TOTE Maritime each announced the construction of their respective second combined container and ships for Puerto Rico trade, with the specific design to maximize cubic cargo capacity by carrying 53-foot, 102-inch wide (2,591 mm) containers.Within Canada, offers 53-foot-container ocean service to and from the island of Newfoundland. Fifty-three-foot containers are also being used on some Asia Pacific international shipping routes. Container 60-foot containers In May 2017, and announced deployment of the first 60-foot intermodal containers in North America. The containers allow Canadian Tire to increase the volume of goods shipped per container by 13%. Small containers The United States military continues to use small containers, strongly reminiscent of their Transporter and of the 1950s and 1960s. These either comply with ISO standard dimensions, or are a direct derivative thereof.

Current terminology of the United States armed forces calls these small containers, and, which correspond with standard sizes 1D, 1E and 1F respectively. This comes down to containers of 8 ft (2.44 m) height, and with a footprint size either one half (Bicon), one third (Tricon) or one quarter (Quadcon) the size of a standard 20-foot, one TEU container.At a nominal length of 10 feet (3.0 m), two Bicons coupled together lengthwise match one 20-foot ISO container, but their height is 6 inches (15 cm) shy of the more commonly available 10-foot ISO containers of so-called standard height, which are 8 ft 6 in (2.59 m) tall. Tricons and Quadcons however have to be coupled transversely — either three or four in a row — to be stackable with twenty foot containers. Their length of 8 ft (2.44 m) corresponds to the width of a standard 20-foot container, which is why there are forklift pockets at their ends, as well as in the sides of these boxes, and the doors only have one locking bar each. The smallest of these, the Quadcon, exists in two heights: 96 in (2.44 m) or 82 in (2.08 m). Only the first conforms to ISO-668 standard dimensions (size 1F). Various markings on the rear end of a containerEach container is allocated a standardized (ownership code), four letters long ending in either U, J or Z, followed by six digits and a check digit.

The ownership code for intermodal containers is issued by the (International container bureau, abbr. B.I.C.) in France, hence the name BIC-Code for the intermodal container reporting mark. So far there exist only four-letter BIC-Codes ending in 'U'.The placement and registration of BIC Codes is standardized by the commissions TC104 and TC122 in the JTC1 of the ISO which are dominated by shipping companies. Are labelled with a series of identification codes that includes the manufacturer code, the ownership code, usage classification code, UN placard for hazardous goods and reference codes for additional transport control and security.Following the extended usage of pallet-wide containers in Europe the EU started the Intermodal Loading Unit (ILU) initiative.

This showed advantages for intermodal transport of containers and swap bodies. This led to the introduction of ILU-Codes defined by the standard EN 13044 which has the same format as the earlier BIC-Codes. The International Container Office BIC agreed to only issue ownership codes ending with U, J or Z. The new allocation office of the UIRR (International Union of Combined Road-Rail Transport Companies) agreed to only issue ownership reporting marks for swap bodies ending with A, B, C, D or K – companies having a BIC-Code ending with U can allocate an ILU-Code ending with K having the same preceding letters. Since July 2011 the new ILU codes can be registered, beginning with July 2014 all intermodal ISO containers and intermodal swap bodies must have an ownership code and by July 2019 all of them must bear a standard-conforming placard.

Handling. A cargo container being transferred from a rail car to a flat-bed truck, lifted by aContainers are transferred between rail, truck, and ship by at., and may be used to load and unload trucks or trains outside of container terminals., tilt deck trucks, and allow transfer to and from trucks with no extra equipment.ISO-standard containers can be handled and lifted in a variety of ways by their corner fixtures, but the structure and strength of 45-foot (type E) containers limits their tolerance of side-lifting, nor can they be forklifted, based on ISO 3874 (1997). Transport.

A portion of a 'double stack' container train operated by, the containers are owned by, the well cars by.When carried by rail, containers may be carried on. The latter are specially designed for container transport, and can accommodate. However, the of a rail system may restrict the modes and types of container shipment. The smaller loading gauges often found in European railroads will only accommodate single-stacked containers. In some countries, such as the United Kingdom, there are sections of the rail network through which high-cube containers cannot pass, or can pass through only on well cars.

On the other hand, runs double-stacked containers on flatcars under. The wires must be at least 7.45 metres (24 ft 5 in) above the track. Also runs double-stacked containers under overhead wires, but must use well cars to do so, since the wires are only 6.6 metres (21 ft 8 in) above the track. Ship About 90% of non-bulk cargo worldwide is transported by container, and the largest container ships can carry over 19,000 TEU (Twenty-Foot Equivalent, or how many 20 foot containers can fit on a ship). Between 2011 and 2013, an average of 2,683 containers were reported lost at sea.

Other estimates go up to 10,000; of these 10% are expected to contain chemicals toxic to marine life. Plane Containers can also be transported in planes, as seen within intermodal freight transport. However, transporting containers in this way is typically avoided due to the cost of doing such and the lack of availability of planes which can accommodate such awkwardly sized cargo.There are special aviation containers, smaller than intermodal containers, called.Securing and security Securing containers and contents.

Main article:There are many established methods and materials for stabilizing and securing intermodal containers loaded on ships, as well as the internal cargo inside the boxes. Conventional restraint methods and materials such as steel and wood blocking and bracing have been around for decades and are still widely used. Polyester strapping and lashing, and synthetic webbings are also common today. (also known as 'air bags') are used to keep in place.can also be directly loaded, stacked in food-grade containers. Indeed, their standard shape fills the entire ground surface of a 20' ISO container. Application in containerSecurity Intermodal containers which contain valuables can be the target of break-ins and burglary when left unattended. In these cases, the container may be fitted with a security system consisting of a motion detector and panel inside the container.

The panel can trigger a siren, strobe, or light to deter intruders, or use a radio signal to alert security guards.Items that were packed incorrectly may come loose and cause a false response from an inside motion detector. If criminals break in by cutting through a wall of the container, the obstructed motion detector becomes useless.

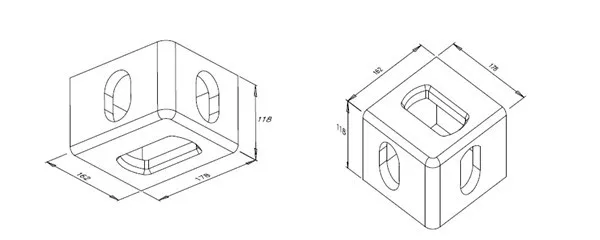

Iso Corner Casting Dimensions

Work well in intermodal containers because they do not require a line of sight to detect motion. The entire container is covered by a volumetric sensing mesh that is not blocked by equipment or inventory. Tomographic motion detection is not prone to misdetection due to dirt buildup as is the case for beams and infrared sensors.Non-shipping uses Containerized equipment. File:Hammelmann Diesel unit – built into containerContainer-sized units are also often used for moving large pieces of equipment to temporary sites. Specialised containers are particularly attractive to militaries already using containerisation to move much of their freight around. Shipment of specialized equipment in this way simplifies logistics and may prevent identification of high value equipment by enemies.

Iso Shipping Container Dimensions Pdf

Such systems may include command and control facilities, mobile operating theatres or even (such as the Russian ).Complete water treatment systems can be installed in containers and shipped around the world.Electric generators can be permanently installed in containers to be used for portable power. Repurposing.

Container City in, Mexico uses fifty old sea containers for 4,500 m 2 (48,000 sq ft) of workshops, restaurants, galleries, etc., as well as some homes.Half the containers that enter the United States leave empty. Their value in the US is lower than in China, so they are sometimes used for other purposes.

This is typically but not always at the end of their voyaging lives. The US military often used its as on-site storage, or easily transportable housing for command staff and medical clinics. Nearly all of over 150,000 Conex containers shipped to Vietnam remained in the country, primarily as storage or other mobile facilities. Permanent or semi-permanent placement of containers for storage is common.

Iso Container Corner Casting

A regular forty-foot container has about 4,000 kg (8,818 lb) of steel, which takes 8,000 (28,800 ) of energy to melt down. Repurposing used shipping containers is increasingly a practical solution to both social and ecological problems.employs used shipping containers as the main framing of modular home designs, where the steel may be an integrated part of the design, or be camouflaged into a traditional looking home. They have also been used to make temporary shops, cafes, and, e.g., the.Intermodal containers are not for conversion to underground bunkers without additional bracing, as the walls cannot sustain much lateral pressure and will collapse.

Also, the wooden floor of many used containers could contain some fumigation residues, rendering them unsuitable as confined spaces, such as for prison cells or bunkers. Cleaning or replacing the wood floor can make these used containers habitable, with proper attention to such essential issues as ventilation and insulation.See also.